Warning / disclaimer – do not attempt to repair mains powered sockets unless you are competent in electronics and never plug these devices into mains sockets with the case open. The repairs suggested here are best performed by qualified technicians as the replacement components must be safety rated.

Over the years the availability of remote controlled power sockets have increased and sets of three can be bought for £15 to £25 in the UK. I have a variety of these sockets around the house, mostly to switch indoor and garden lights via remote control. Unfortunately a number of sockets are now faulty, cast aside, and I’ve ended up buying a new set rather than investigating why they have failed.

To help save the plastic from land fill and follow my rule — don’t throw it away — I decided it was time to act and see if repair is possible. Faults on three of my sockets are all similar – the red led light illuminates on command and the relay clicks on, powering the load, but after a short time the relay clicks and power to the socket goes off. The red light appears bright at first but then dims after a few seconds but stays on even though the relay is off.

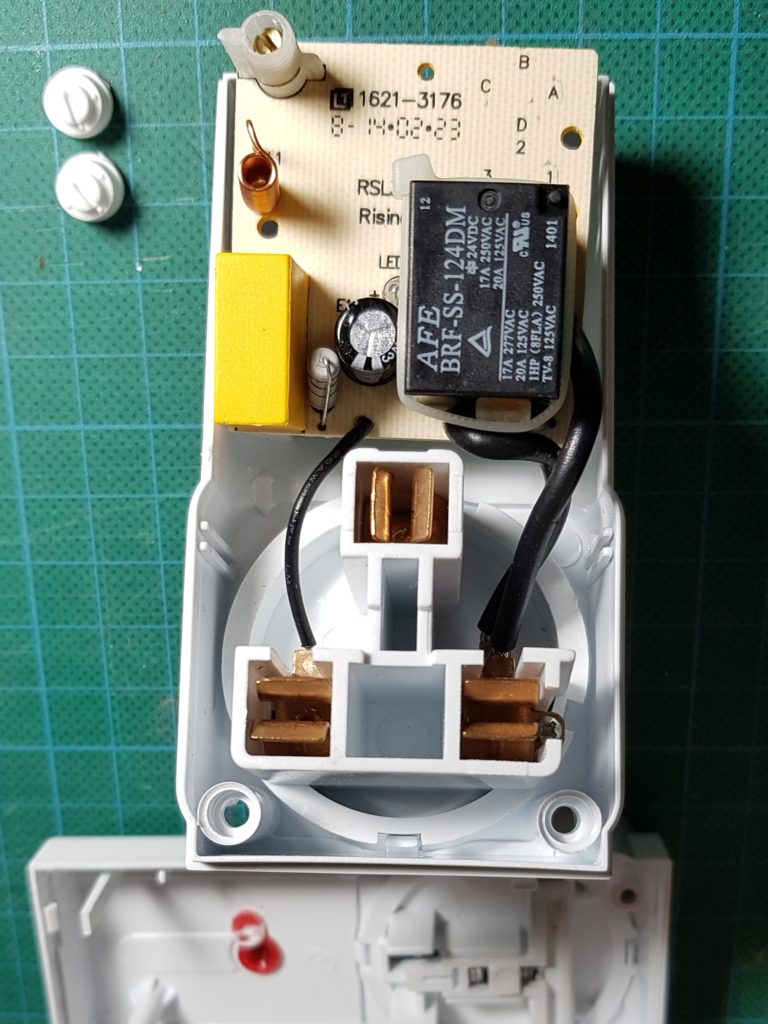

To open the socket I levered the circular cover away at the base of the three pin plug using a small screwdriver. This uncovers two fixing screws that need a special thin driver bit. Two of my sockets have star shaped Torx fixings with a tiny centre pin. The other socket pictures above uses a three blade bit.

After removing the two fixings, I held the front round socket in place as I pulled apart the top cap from the socket – this avoids the little shutter spring disappearing off. There are two round control switches that also fall out when the circuit board is removed. No need to worry which setting they were on as they can be re-inserted in any position.

In this first socket I found a small circuit board, consisting of a capacitor dropper – the rectangular yellow one – and half wave rectifier to provide around 24v dc to power the main control relay and control circuitry.

Remote control socket type 1

There’s a temperature fuse, marked SET K1 102 degC N04, in series with the relay coil attached to the relay with a cable tie. I suspected the 220µF 35v electrolytic reservoir capacitor – the larger black one – in the first socket and found a 63v replacement to try. It was a little larger but same spacing and fitted in place. When put back together I found the socket worked again with the relay staying energised.

I left this on soak test driving a load and went on to open the next faulty socket. After repeating the same trick of replacing the reservoir capacitor and putting back together, the socket still failed, relay clicking off after a few seconds. A great example of jumping to conclusions and not bothering to diagnose what the fault actually is! Identical sockets, same symptoms but different causes.

So I hooked up a thin test lead to measure what was happening inside the socket while reassembled. This found the voltage across the relay started off around 16v as the relay clicked in but quickly dropped to below 7v as the relay clicked off. Hmmm. Not enough power getting to the relay. There’s a reverse blocking diode across the relay to kill the back spike as the relay disconnects. It measured fine as a diode but I wondered if it could be breaking down like a Zener diode. Swapping the diode made no difference.

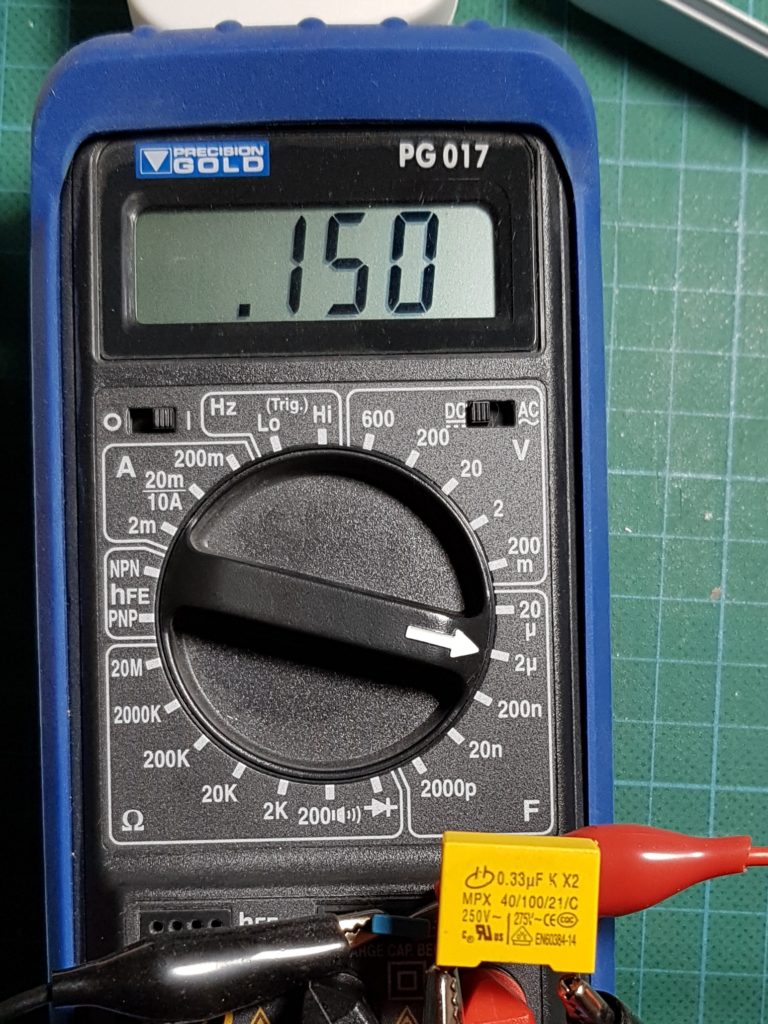

I changed the test lead to measure the voltage across the new 220µF reservoir cap. It showed around 25v with the relay off and down to 8v with the relay on – so off-load voltage is right but either too much load current or not enough drive. The red led is wired in series with the relay coil so it explained the dimming effect as the current drops off following the voltage drop. So the only component left to explain the low power reaching the relay was the 0.33µF mains voltage dropper capacitor. Obvious really but it’s not a component I expected to fail. These yellow or blue polypropylene rectangular caps should be reliable.This one has plenty of standard logos and 40/100/21/C climate test proclamations! This means -40 to +100 deg C for 21 days so hardly stressed at all in the house!

Not in this case. I removed the cap and measured it using a capacitance meter, see below. It showed just 0.15µF. Ouch, that’s under half the value needed – no wonder the relay was dropping out.

Dropper capacitor reading low

So if you find your old Maplin / Lidl / Olson remote control sockets are no longer staying on when you want it may just be due to a faulty capacitor or two that cost less that £1.

Back to the first socket left on soak test – it failed, with the replay dropping out after a few hours. Changing the dropper capacitor fixed this one as well. So this one needed both the reservoir and dropper capacitors replacing although just changing the dropper would likely have fixed it.

A word of warning – a mains dropper capacitor MUST be rated to fail safe – open circuit. If it fails short circuit it effectively applies mains power – up to whatever your ring main trips out at — worst case 32A — directly to the reservoir capacitor and control circuitry which will likely ignite before any temperature fuse acts! Remember often there’s no standard fuse in these remote control sockets – the fuse is in the plug that plugs into the socket – the wrong place for a short circuit to blow.

So unless you understand how to select safe components of known quality or can take your broken sockets to a recognised repair cafe, it’s best to recycle the faulty socket. It may only cost a few pounds to replace the capacitors but getting it wrong could burn your house down, so don’t risk it.

It’s a similar story with any wall-wart type mains adapter that are now used for almost all home appliances from phone chargers to low voltage lighting. Gone are the old fashioned costly transformer, replaced with cheap capacitor mains droppers. They are often left plugged in all the time and that capacitor is working 50 times a second to prevent failing short circuit. It only takes one cycle to blow a hole in the insulation and subsequent rush of current to raise the temperature and melt the plastic. So in a way it’s good that the relay in my socket gently switched itself off – I should have listened to its call – I’m failing safe!

PS: A quick Google found Big Clive’s Youtube channel has an autopsy on a similar remote control device – Clive found the fault with the dropper capacitors, in his case smaller 0.22µF devices. I admire Clive’s videos where he digs under the cover all sorts of electrical devices with patience and calm delivery. He shows a second socket with a scorched discharge resistor and vaporised PCB that’s a great example of what can happen if a component fails in these devices with no safety fuse. It demonstrates the reason that mains plug fuses are surrounded in sand in a tough ceramic housing to absorb the power surge when it blows.

Leave a Reply